-

FIT MOULD have served in mold industry for 20 years.

Our facilities equipped with all kinds of leading machines. In our mold room, we have 5 CNC machines, 10 EDM machines and 8 Wirecut machines. the largest machining size is 2 meters. There are other modern appliances such as precise Wirecut, mirror EDM, automatic CMM. In our molding room, we have molding machines from 80Ton to 650Ton. With all these capacity, we make 40 molds monthly...

-

Quality assurance at FIT MOULD is an integral part of our daily activities; and is our top priority. Our quality program is comprehensive and is coordinated across all manufacturing disciplines. Every employee of FIT MOULD is held accountable for monitoring and improving quality.

During mold manufacturing, every individual is empowered to take responsibility for fully inspecting the...

-

FIT MOULD has a skillful sales team who is the main window for customer, each project begins with a thorough understanding of your needs and specifications. We communicate with customers on line, no problem in time difference, we always give you quick reply and solutions for your questions.

Each project will be assigned to a project engineer who will in charge of the whole project, from the very beginning till the mold and part approval, nothing will be missing and hidden. Engineers...

-

1. Do you build hot runner plastic moulds?

Yes. We build hot runner Plastic Moulds and specialized in many different systems, such as DME, Master,Mastip,Hasco,Yudo, Incoe, Husky,etc. The manifold recommended for your tool is selected to meet your individual needs.

2. What types of files do you accept (drawings)...

- Design & Engineering

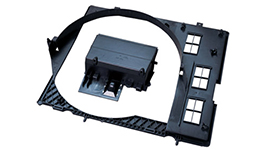

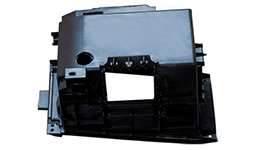

- Mold Making

- Moulding

- Stamping Tools

- Die Casting tools

-

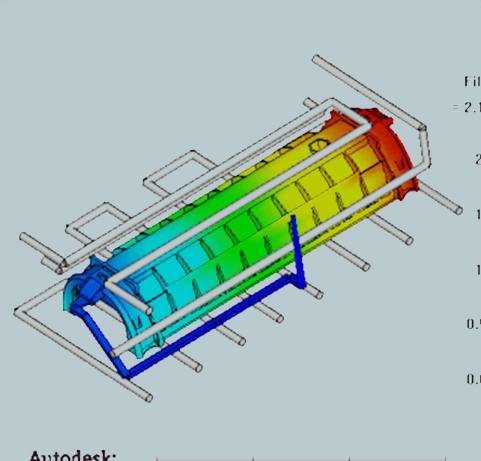

Design & Engineering

There are 20 engineers in Engineering Department. Most of them have been in mold design field for more than 10 years.Our engineering team will review your design for manufacturability, offering suggestions for improved processing, cycle time or part. -

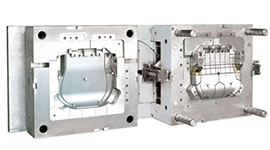

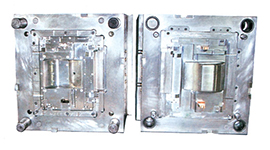

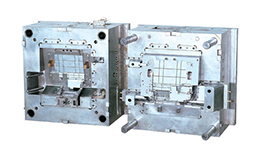

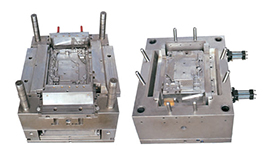

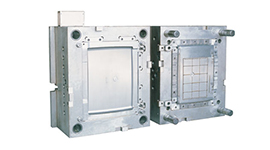

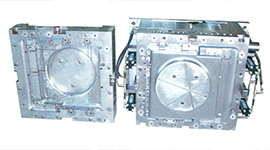

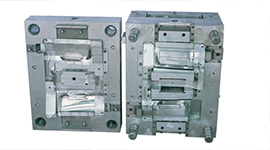

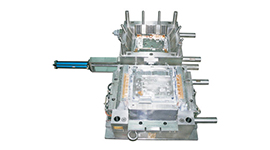

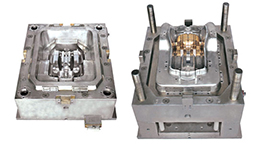

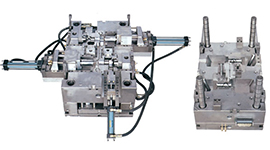

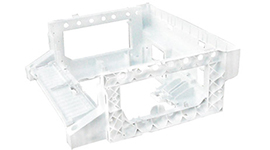

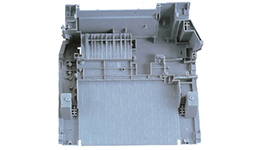

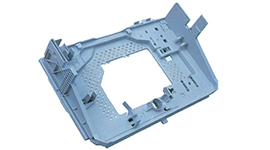

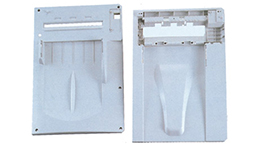

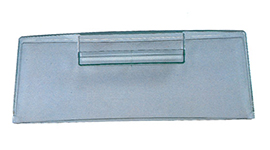

Mold Making

The combination of our extensive Engineering Design capabilities, state of the art CAD-CAM system platform,CNC machinery, and Team Mold Building approach, allows us the competitive advantage needed in today rapid turnaround environment. -

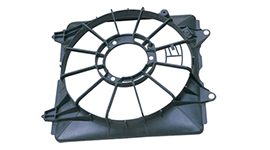

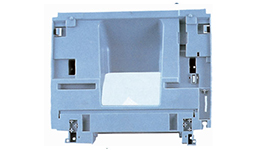

Moulding

FIT MOULD injection molding division utilizes a variety of molding machines from 80Ton to 650Ton, We can manufacture all plastic resin applications, including rigid and flexible injection molding, precision, two shot and high speed molding. We offer a prompt... -

Stamping Tools

Fit Mould can also make and control good quality for stamping tools.

Product Range:

Single Stage Blanking/Bending Tools

Progressive Tools

Deep Drawing Tools...

-

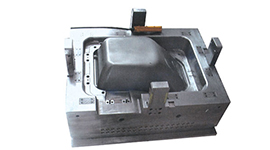

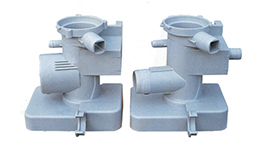

Die Casting tools

Fit Mould manufacture and maintain a number of tools for both Aluminum and Mazak material for a number of foundries, the design process and tool complexity are very similar to the Plastics industry with a lot of the CAD requirements being the same, all the...